Did I take a 9 month break from the blog intentionally? No. In fact, I don’t think I ever really announced this on the blog but I am getting married this year! Alongside the PhD, PTVL teaching, my other job as an Analyst, the podcast, sewing, running, and everything else, I decided to sew my own wedding dress. Hubris right? Well not only that but in fact I am sewing;

- My Wedding Dress

- My Evening Wedding Dress (I can’t dance in a long dress, I will fall over! Plus this can be worn in the future more easily!)

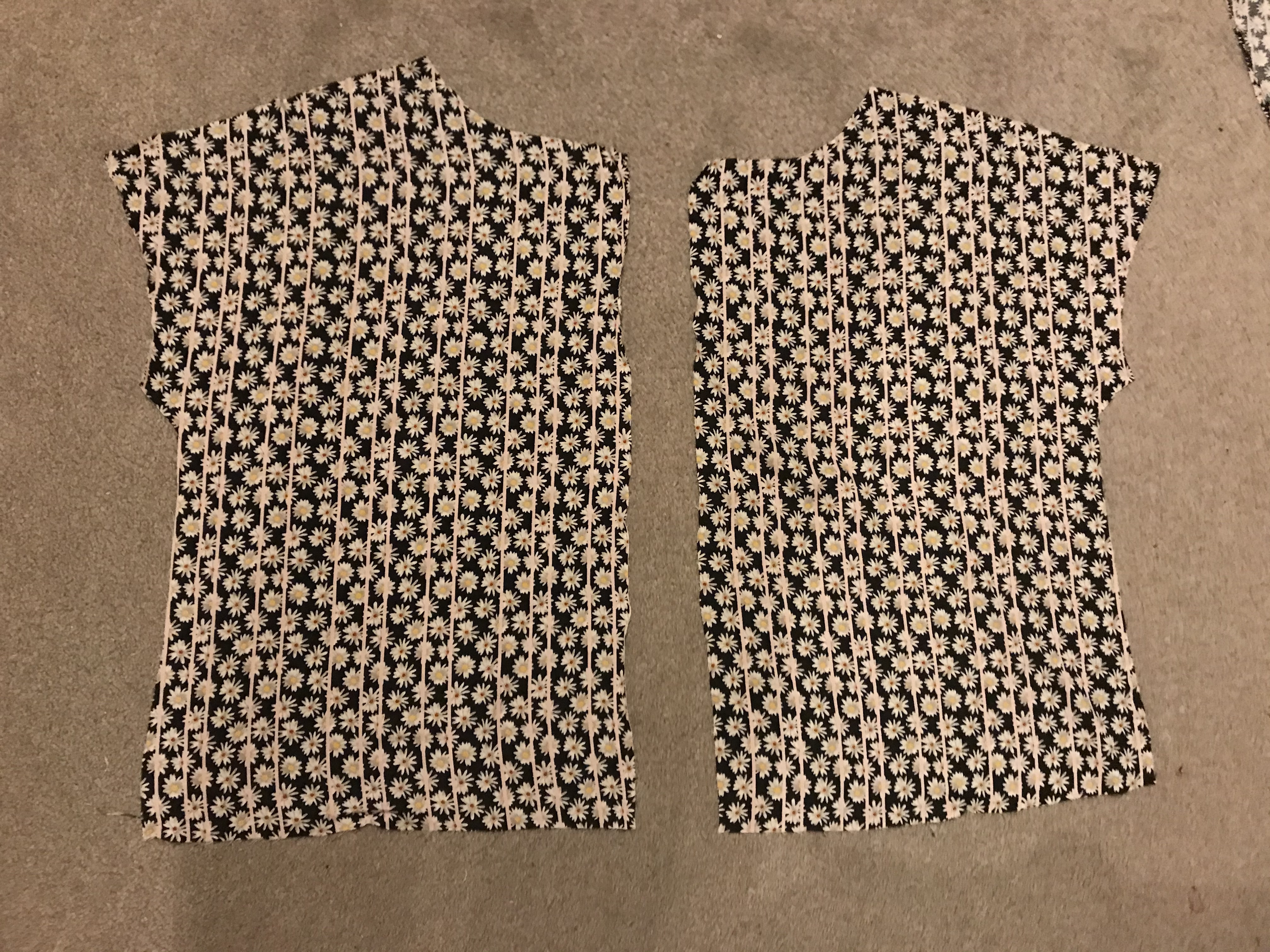

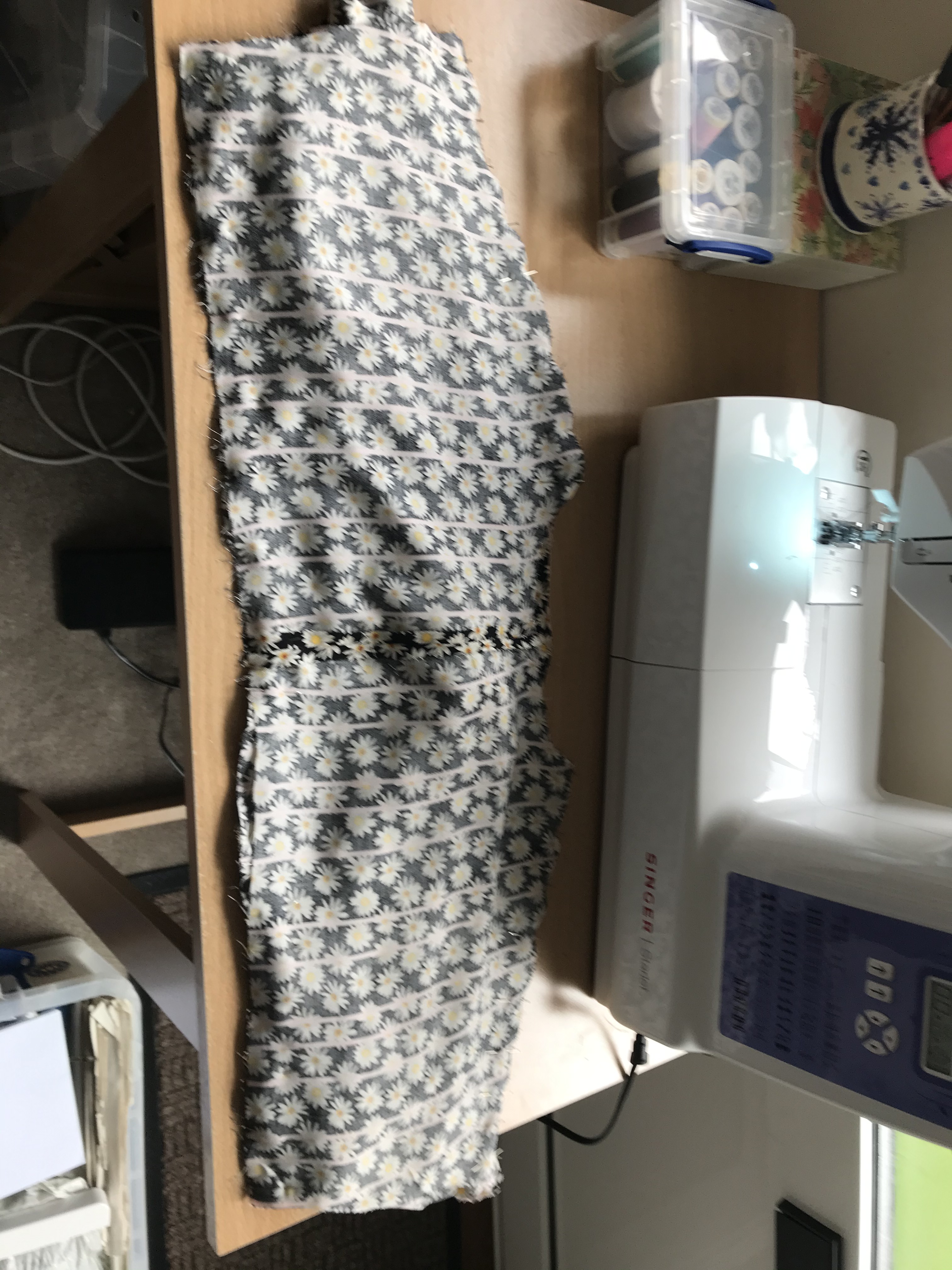

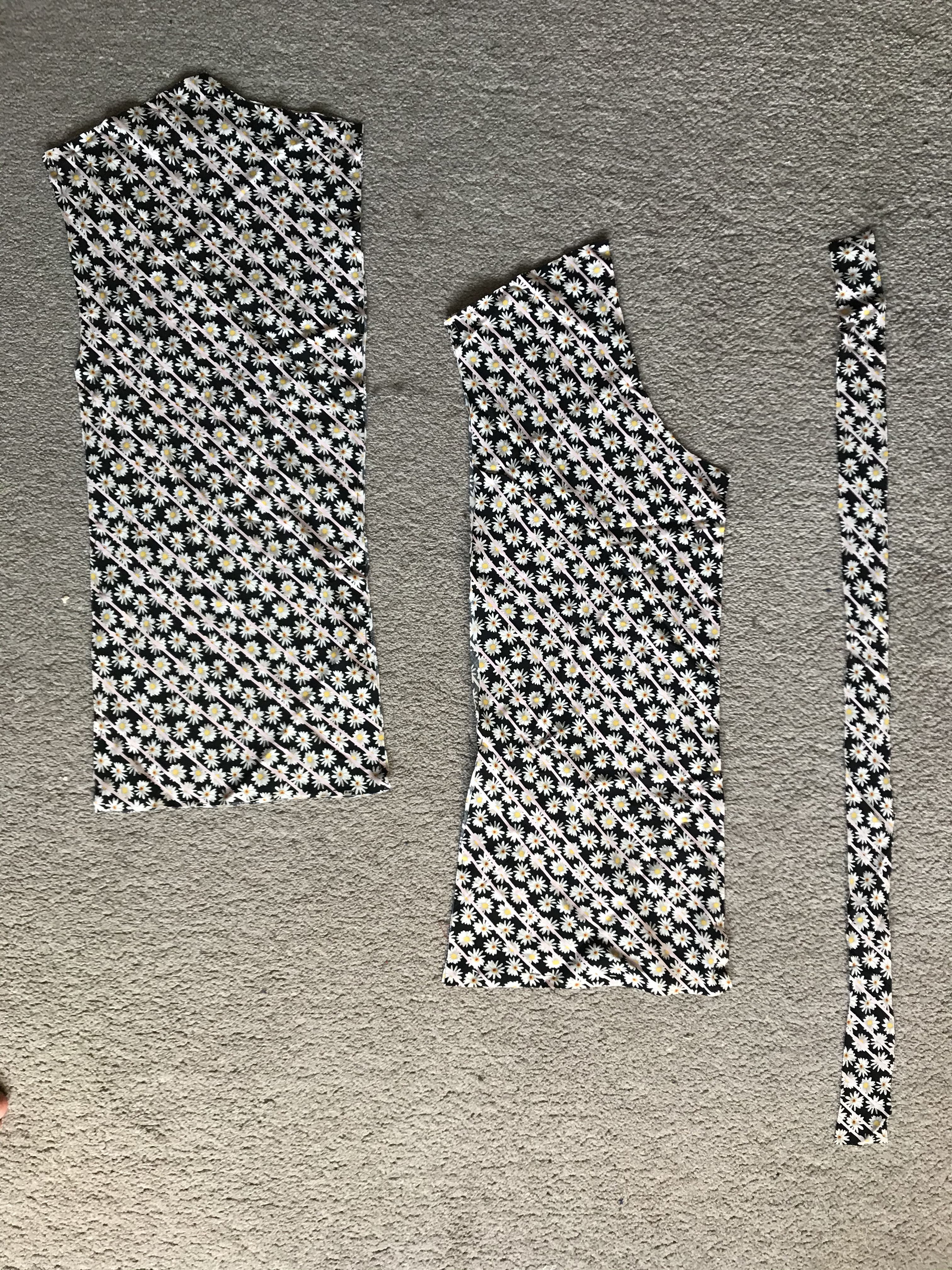

- Four Bridesmaids Dresses

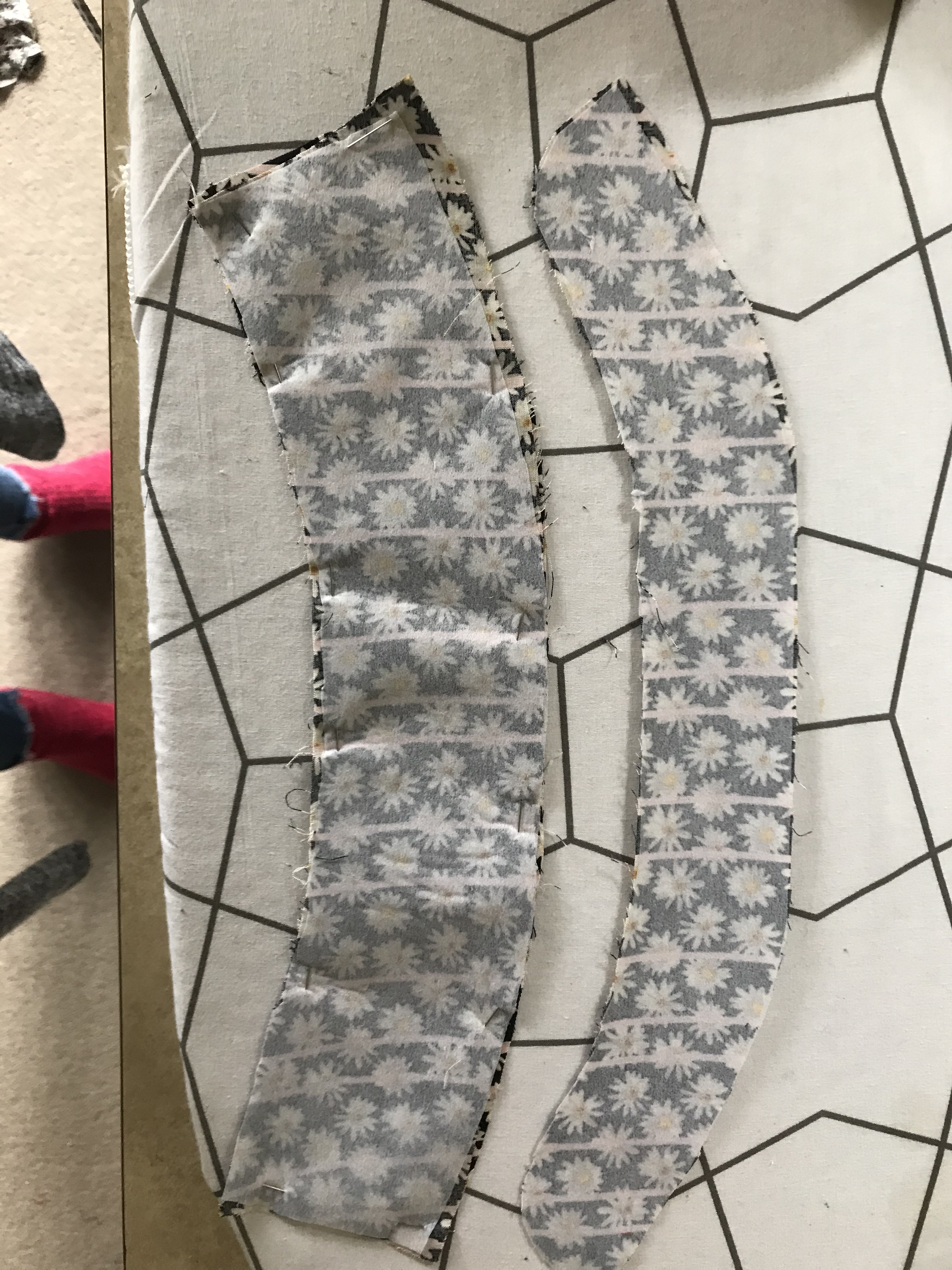

- Four Ties For Groomsmen

- A Shirt For Adam

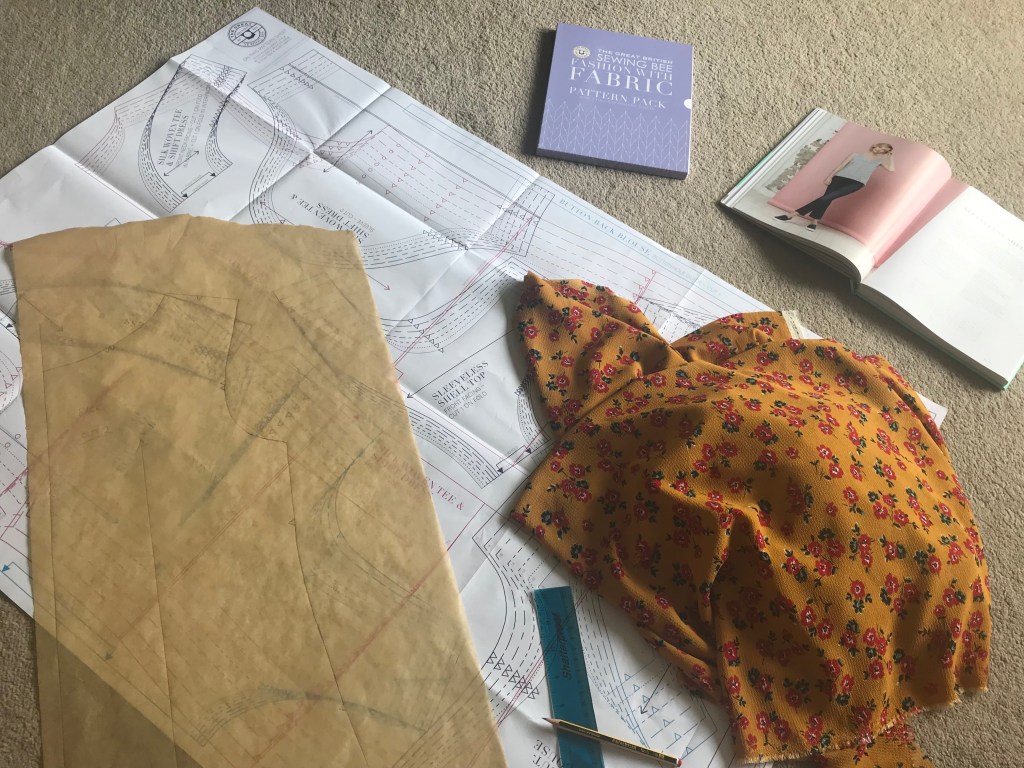

So it’s two months to go, and most of the above list isn’t complete; although I did reach what I think will be the final full toile of my wedding dress last night – still a couple of bits to fix but we are 99% there. Am I stressed? Well yes and no. Obviously two months isn’t a desperately long time. However I am an extremely speedy sewist so I’m not too worried about it all. My main stress until two days ago was the all of the shades of velvet I’d carefully chosen were out of stock for my bridesmaids dresses. Fear not! It’s my own fault for trying to buy it in August. Now that it’s September all the velvet is back in the shops and I’ve ordered what I need so we can get going with those when it arrives. So why am I writing this blog? Well for one thing I have steroid insomnia and I woke up at 4:30 in the morning thinking about my wedding dress sewing experience. The main reason though is that I don’t think we speak enough about sewing your own wedding dress as a project. It seems mystic and far off when the reality is that if you’ve made an evening dress, you’ll probably be able to manage a wedding dress. Nonetheless it can be a taboo subject so I thought it might be useful to share my thoughts and tips for anyone who wants to give it a go.

Top Tips For Sewing Your Wedding Dress

To be clear this is not going to be a highly technical blog about basting, seam finishes, and sewing techniques. Not only are those things radically different depending on the style of dress you choose but also that’s not really what you need to know about sewing your own wedding dress. The fact you may need to look up how to finish a seam is not what will get on your nerves. Wedding dresses are inherently emotional projects. They are also prime real estate for anyone who wants to tell you how you should be sewing your dress. Avoid those people like the plague. The tips I want to share with you are more mindset based. They are to help you through the minefield and hopefully show you by the end that it’s okay to do this exactly how you want to regardless of anyone else’s opinion.

It’s Your Dress.

This sounds glib but at the end of the day the only person wearing this dress is you and even then you’ll only be wearing it for about 12 hours. That means your priorities should be (in this order); comfort, practicality, looking beautiful. Pleasing others is not and should never be on this list. Brides look beautiful when they feel beautiful, not when other people tell them they look it. I once worked a wedding where the bride was 4’11” and as a result she had chosen a stunning 1950s style knee-length fit and flare dress. She looked radiant and it suited her to a tee. Just before she went to walk down the aisle, her mother turned around to her and said ‘oh I wish you hadn’t chosen that dress’ and the bride looked distraught. Her mother went off down the aisle with a groomsmen and I pulled the bride aside for a chat (the role of an event manager can be extremely varied) and I asked her to tell me why she’d chosen this dress. She started telling me how self-conscious she felt about her height, the fact she hates long dresses, how much she loves to dance, how her and her fiancé enjoyed going to lindyhop and swing dance classes, and how unique she felt in her dress. As she told me she became much brighter because she truly loved her dress and felt beautiful regardless of the wisdom her mum had decided to impart. It’s about how you feel in your dress and if someone says to you ‘oh I’m not sure your dress is quite you’ or ‘I would have worn X’ feel free to tell them to wear that to their own wedding or my personal favourite comeback ‘its a good job my wedding isn’t about your outfit’. If you want to feel slinky and svelte? Do it. If you want to live your cinderella dreams? Crack on with my blessing. If you want to go simple and loose? Enjoy! You generally get one chance to sew your own wedding dress, so do it the way you want to, and do it with style.

Only share your progress with people whose opinion you trust.

At the end of the day, sewing your wedding dress is a whole different ballgame to buying one. When you buy a dress you have the stress of finding something you feel perfect in, and to be clear, I’m not minimising that. Saying ‘Yes’ to the perfect dress is not the stress-free single trip that we are led to believe. But. And its a big but. Sewing your wedding dress even if you are using a pattern out of the box will still be more challenging because you have to go through the ugly duck phases where the bust isn’t right or the satin is pulling or the lace isn’t behaving, or the pattern is drafted for someone who is 6ft 4 and you need to adjust it. So as you are going through all of this there are two types of people you may want to show it to; people who sew and can give you genuine advice when you are stuck, or, very close friends or bridesmaids who have no idea how to sew and can just be your personal cheerleader. However when it comes to people who can’t sew here is a word of warning, choose someone who will just be lovely and happy that you are sewing your dress. Do not show your progress stages to anyone who is likely to say any of the following; “I don’t like that bit; why does it look so weird in x place; are you sure you want that design feature; I think it would be nicer if it looked like x; is it supposed to do that?” The progress stages are your proof of concept, your workthroughs, and what you don’t want to do is have your elation at progress dampened by people who think its rubbish because they don’t know these stages are very standard in a sewing project like this. When it comes to people who do sew, just make sure you are clear about the stage you are at and the type of feedback you would like to receive. Tell them it’s a first draft or tell them ‘I just can’t get the fit on my hips correct, can you help?’ but its important to be clear about the feedback you would actually like to receive or else we risk returning to Outcome O. So named(by me) because it turns your pride and elation into ‘oh’ and makes you not want to keep sewing.

Try on every wedding dress you can get your hands on.

A harsh truth of wedding planning whether its venue, flowers, or your wedding dress you will think you want one thing and then you will hate it. The issue is when you are making your dress its a lot of time and investment to put into something you think you will want to wear. When I first went wedding dress “shopping” or ‘our market research trip’ as my mum and sisters referred to it, I tried on every style, every colour, and realised quickly that although your wedding is the chance to wear the dress of your dreams, its also one of the few days that is totally yours. It’s for you and your partner to celebrate a beautiful life event and as a result you want to be comfortable, practical, and feel your best. It will be of no surprise to any of you that my dress is not a confection of tulle and petticoats. But! I had to try on dresses like that just to make sure it wasn’t what I wanted. I tried on the most stunning and enormous dress. It was beautiful, I felt like a princess, and in the photos I look gorgeous. In reality it was a standing still dress. It looked incredible stood on the box in the bridal shop but then you get off the box and walk around and you realise that having the turning circle of a 3.5 tonne van may not be ideal and that’s before we get to the thorny issue of trying to go to the loo. For some people that is their dream and that is brilliant! For me it would have driven me insane in about 5 minutes and I would have felt silly which is not what you want on your wedding day. I only know I don’t want that because I tried it on. So try everything. Try styles you think you’d hate. Try styles you’d never dream of. Try anything and be open to suggestions and then take a million photos. My core conclusions from my shopping trip were as follows:

- Enormous dresses are beautiful but not for me.

- Any dress with a corset or corselette is not the best friend of an asthmatic.

- There is such a thing as too plain.

- Ask your nearest and dearest to be honest with you and make sure they are on your wavelength. I picked up one dress and my sister remarked ‘it’s fine if you want to look like Glinda the Good Witch’ and she was unerringly correct. The thing is that wouldn’t have occurred to someone else but I would have realised I looked like that 5 minutes before going down the aisle so I’m glad she said it then.

- First thought best thought. If you look in the mirror and think you look like a cake topper then move on, even if everyone else thinks you look stunning.

- Make sure you can dance and breathe and move in the style you like.

- Consider the cost of the fabric and the finish. My favourite dress I tried on was about 80% perfect. I liked the style as a starting point, I liked the way it made me feel, and I really liked that I probably wouldn’t need more than 4m of satin to achieve it. (Side note; the one in the shop didn’t have french seams for £1800 I would expect them on Satin?!)

- Do not feel guilty for being fussy. You know the saying ‘measure twice, cut once’? Well when it comes to wedding dresses it’s more like a 100:1 ratio.

There are more shades of white than Dulux could dream of and that’s before you get to cream.

This may have been the part I found the most frustrating. Once you enter the world of wedding dresses white isn’t white. You suddenly get white, off-white, pure white, eggshell, ecru, blush (which is a pink type of white), and let’s not forget ivory. It is very very important than you choose the right colour. It’s also mind-numbing. Also bear in mind how colour and tone is created in a wedding dress. Particularly in more voluminous dresses the colour can be built by layer. A white overskirt and white tulle with a blush lining which would give an overall blush finish. The next joy on your plate is translating this to fabric shops who do not work to the same colour standards of the bridal industry, because NOBODY does. I went with a sort of vintage off-white. It looks nice next to my skin, it works well with the style of dress I am making, and most importantly for me, it was clearly identifiable in the fabric shop. All I’m saying with this one is mentally prepare yourself to care more about the colour white than you ever have in your life but also remember, it’s not that deep. What matters is that you feel comfortable wearing and working with your fabric. It’s not your job to sell yourself on the very specific tone of ivory blush that frankly doesn’t exist outside the lighting of that bridal shop. Take it back to basics.

It’s going to take months and you’ll still be working on it until the week before.

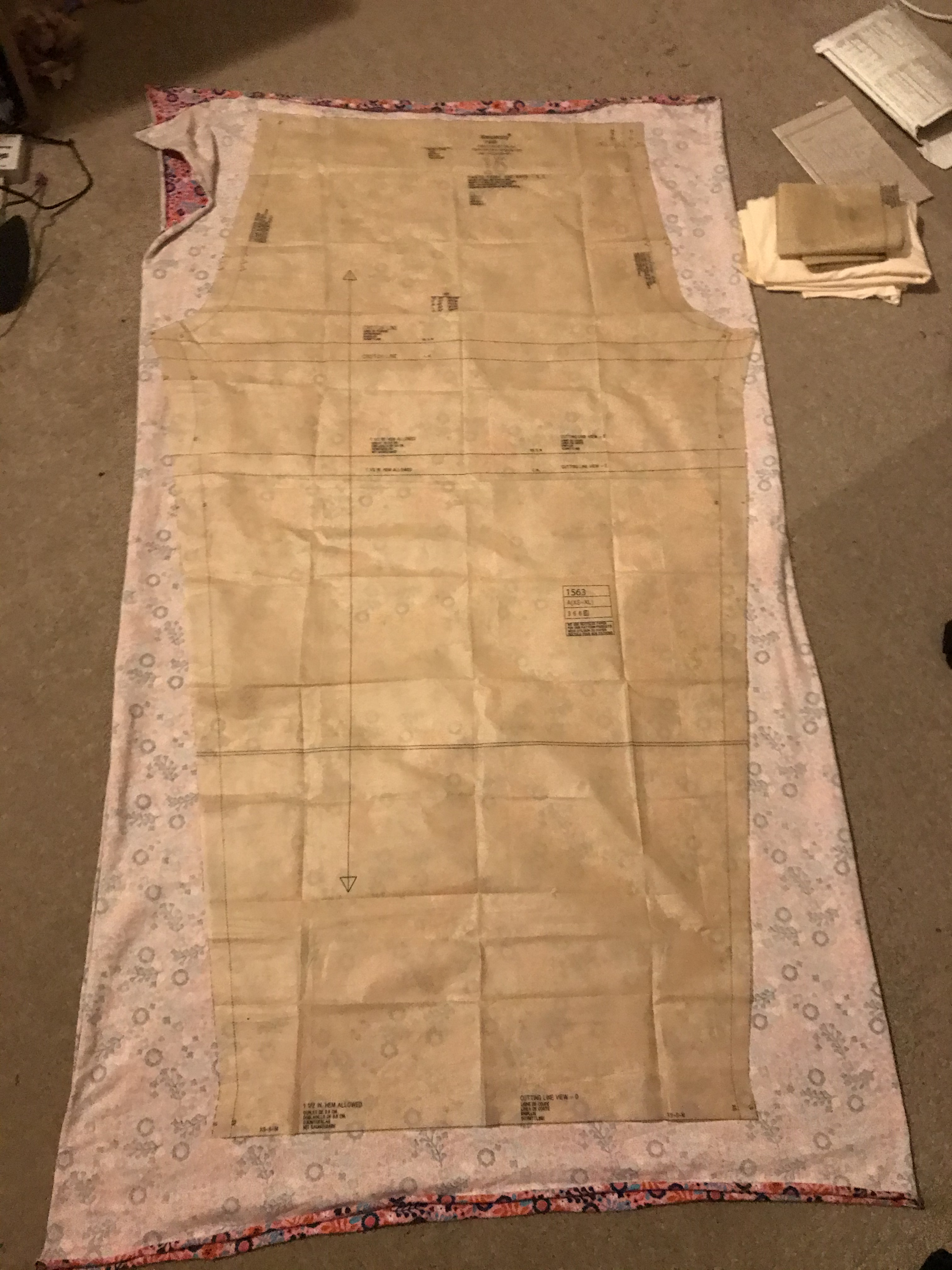

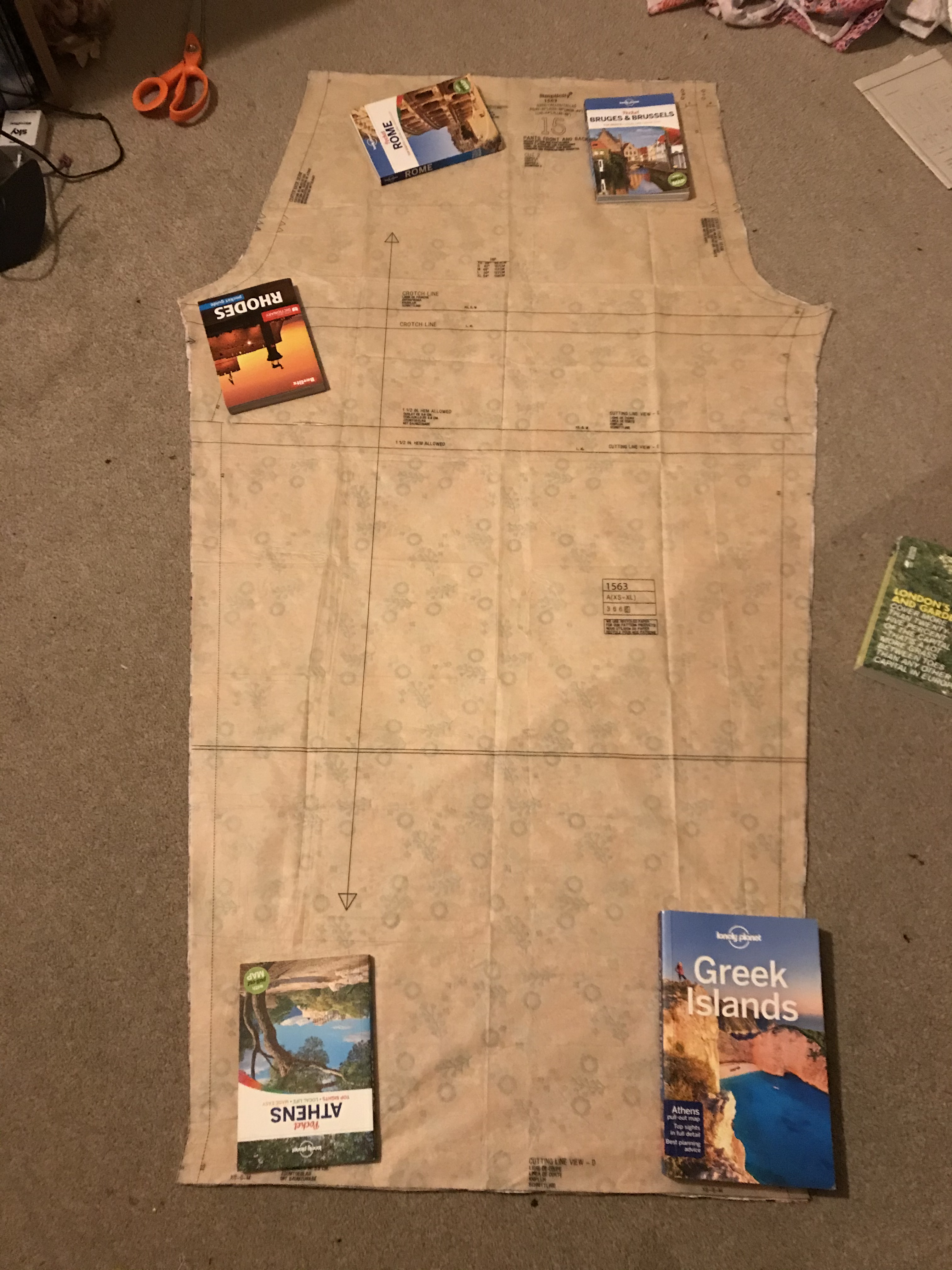

This is normal. This is unavoidable. You may buy a wedding dress a year out from your wedding but you’ll be in the shop 3 months before for alterations and 1 month out from your wedding you’ll still be getting any snagging done. This isn’t like any other project you will do. You will start a year out with the designs. You might even buy the fabric at this stage or go trawling through samples to find what you like. You’ll do a toile. You’ll love it. You’ll change it by a fraction and suddenly ruin the whole thing. You’ll move from messy toile fabrics to fabrics similar to your dress and the design suddenly won’t work. You’ll lose weight. You’ll gain weight. You’ll go on holiday. Life will happen. You will have deadlines that mean you have to put your wedding dress on one side for a month. Your opinions will change on how you want your dress to look and that is all natural and part of the process. I’ve had lots of people tell me I’ve left everything too late but no one else knows what too late means in your context. I don’t know if its because I am doing a PhD, which is the academic equivalent of sewing your own wedding dress, but I feel very sanguine about working through drafts and drafts for months whether its my thesis or my wedding dress. It makes it easier to know that you’ll be working on it constantly for 9 months to a year and even if you prepare and plan you will still be hemming it the week before so why stress? Which brings me on to my next tip.

Like any project, figure out how you work best.

This is starting to sound like an academic skills blog but read on I promise it’s about sewing. To be brutally honest if I had to sew my wedding dress everyday for a month I would go stark-raving mad. I’m not a little and often person when it comes to creating. Just as with my thesis I am a ‘think about it for 6 weeks then suddenly get struck by inspiration’ kind of person. I need thinking time. I need to mull. I need to consider what I like and what I don’t and crucially why I don’t like it. However this means that once I do decide what I want, I choose a day or a night (normally a night when Adam is out at Jujitsu) and just crack on for 4-8 hours. For someone else the way I work would be intolerable or frankly impossible. There are people who would love to chip away at the project every day. There are people who start their dress two weeks out. There are people who hand sew the entire thing (and to be clear those people are insane) but the point is, you have to figure out what you need and how you best work. I fully intend to go to the Southern Sewcial in October to finish off my panic sewing. I know there will be panic sewing so why not actually book in a day to do it!

Start Somewhere. Start Anywhere. Just Start.

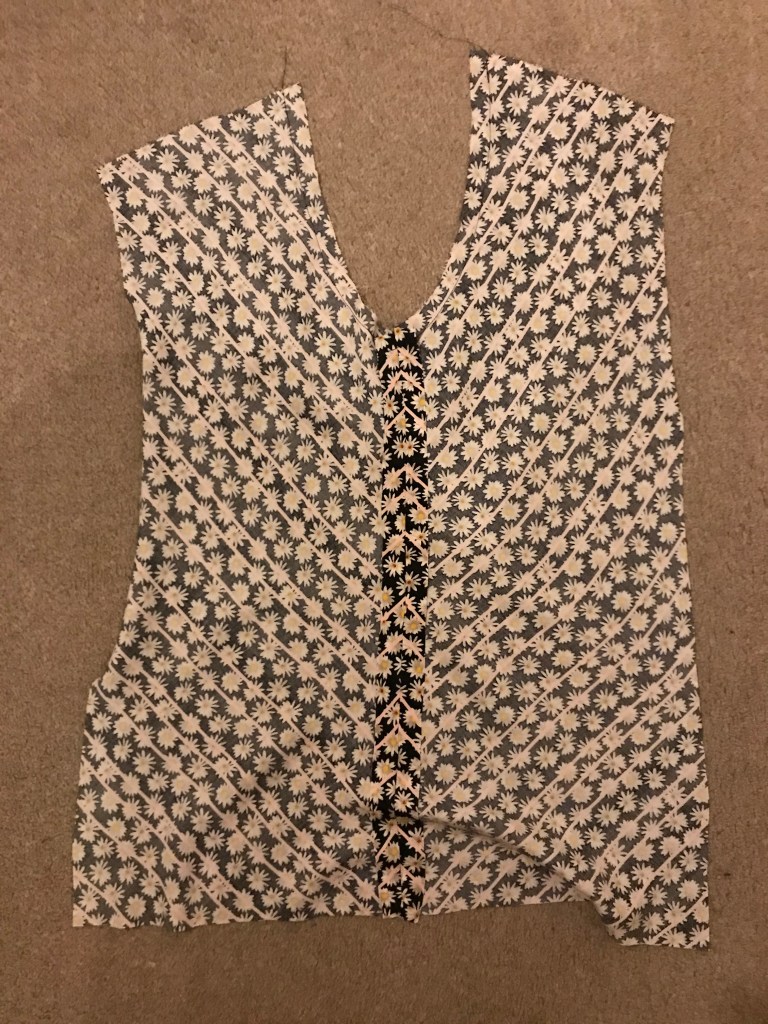

Its daunting. I’m not going to sit here and say that it isn’t because it is. And frankly it’s supposed to be. You are preparing for a watershed moment in your life and most likely in your sewing career. It’s scary and do you know what? You’re allowed to stress. Even on your toiles you are allowed to stress about it but it’s so much more important to make some progress than none. People will build up wedding dress sewing as the be all and end all but it just isn’t. You are making a dress. You are putting a pattern together just like you do the rest of the time. If, like me, you had a couple of patterns as starting points then I recommend writing your own instructions as you go, but at the end of the day it’s just another sewing project. Admittedly the fabric is more expensive and the stakes are higher, but don’t let that deter you. Your first toile of your wedding dress is always going to be a proof of concept. You’ll love it. You’ll hate it. You’ll know what needs fixing. You’ll see the germ of your design starting the emerge. No matter what you have to start somewhere and it’s never going to be perfect the first time. My way of tackling the existential dread I had about starting? I put a 30 minute timer on and dashed out a full toile. It was basted together in rubbish acetate that cost me £4, the length of the front and back didn’t remotely match. The bust was too small. The train looked like a tiny puddle that had got caught in my sewing machine. The straps were wrong. The shape of the skirts didn’t match. But none of that mattered because I could see that my dress was in there and it would work out eventually. Think of it like a concept car. The doors may not open. None of the electrics are in it. It’s not truly a car. It’s an indication that your concept works and it gives you a road map.

Finally, remember that in a year’s time you will not care how long the seams took or how frustrating rouleau loops and covered buttons are, or how many toiles you went through, because its frankly the least important part of the day. Getting to walk down the aisle and marry your favourite person on the planet should not hinge on your dress. I would marry Adam in my pyjamas with no make-up on at a registry office at 10:00 in the morning on a random Tuesday with no one else there. It’s lovely to get to wear a beautiful dress and be surrounded by friends and family to celebrate your wedding, but never let the dress get in the way of the wedding.

P.S. If anyone, and I do mean ANYONE, decides to tell you how you could have made your dress better on the day of your wedding, have them removed from the venue.